You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationAI in the field: video portrait of Benjamin Kisliuk

VolkswagenStiftung

Benjamin Kisliuk still has to smile when he thinks back to the beginnings of his current research project. In January 2020, the computer scientist began working at the DFKI Laboratory Lower Saxony, the Osnabrück site of the German Research Center for Artificial Intelligence (DFKI), as part of a team developing autonomous robotic systems for agriculture. The idea: the robotic device is parked at the edge of a field and started up. Over the next few days, weeks or even months, it moves around – completely autonomously – and collects a huge amount of valuable data: How well are the plants growing? Do they have enough water? Are any pests present? What is the soil like? If it runs out of power, it recharges itself from a solar-powered charging station. “Our vision was a large, 200-kilogram vacuum robot for the field. You press the start button once and maybe come back in a month or so to make sure the cameras are clean.”

The problem: the mobile robot platform on which all the cameras and sensors were supposed to maneuver through the fields simply failed arrive. Kisliuk’s colleague had ordered delivery from Norway to DFKI Osnabrück, where he works as a doctoral student in the field of agricultural engineering. But at the beginning of 2020, the world was in the midst of the corona pandemic that caused global supply chains to collapse. “It actually took a year and a half for the device to finally reach us,” says Kisliuk. “That was nerve-wracking, of course. Most of the preparatory work had been completed, we had carried out tests with a smaller robot and sent out drones to take aerial photos. All the measuring equipment was also ready, and our fingers were itching to finally get started.”

Collecting data in the field

Instead of just waiting for the robot to be delivered, Kisliuk and a colleague simply roamed the fields themselves, carrying the measuring devices weighing up to 20 kilograms on their shoulders. In this way, they collected the data that the machine was supposed to collect. In the next step, the two researchers wheeled the devices across the field in a handcart. And when the platform finally arrived in Osnabrück, it was still a long way from being able to move on its own. “The navigation software hadn’t even been programmed yet,” says Kisliuk. And so, the machine made its first laps of the fields by remote control, with the researchers walking a few meters behind it and using a joystick to set the direction. “Of course, that was just a primitive improvisation, but it was the only way to get the machine moving.”

Moritz Münch for VolkswagenStiftung

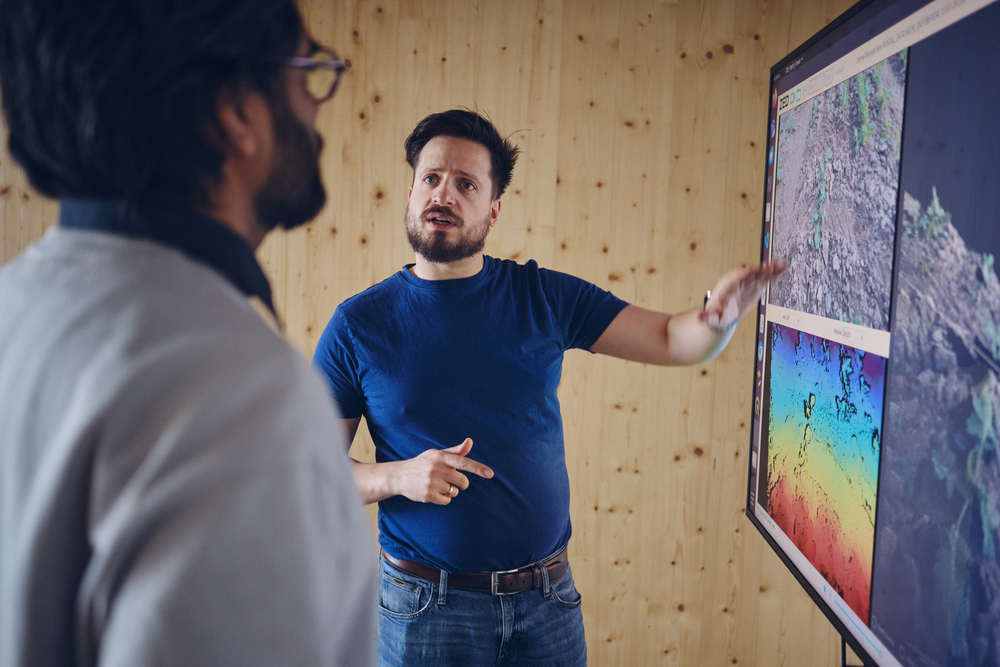

Benjamin Kisliuk and his colleague Gurunatraj Parthasarathy (left) discuss images taken by the robot with various cameras.

In the summer of 2023, the time had finally come. By then, Kisliuk had programmed the navigation software, teaching the robot how to move from A to B, which path to take through a field full of crops, and which areas to avoid. “Then we decided: Now we’ll really set the robot down at the edge of the field, press start button and let it drive itself.” And that actually worked, although the device cannot yet be left alone for safety reasons. The field robot already has a charging station – solar-powered, as envisaged in the initial concept. It can already park itself, but the charging process is still being worked on. This is challenging, explains Kisliuk. “The robot’s battery must be positioned with centimeter precision under an induction plate, otherwise no energy will be transferred.”

From space to the field

Kisliuk came to robotics after completing his master’s degree in computer science in Osnabrück in 2017. “I realized pretty quickly that I want to work in application-oriented research. I like the idea that the technical solutions I work on will ultimately be useful for a large number of people.” At the DFKI location in Bremen, the opportunity arose to work on a project for the European Space Agency. “For a young robotics researcher, that was of course a dream come true. I can still remember how good it felt to be able to tell people at a party that you work in the field of space robotics.”

Nevertheless, Kisluik has not longed to return to space since he moved to the then newly created “Lower Saxony Laboratory” at the DFKI location in Osnabrück in 2020 (now an independent DFKI site) and swapped Mars for a field on a farm. “Of course, at first glance, the surface of a planet is more exciting terrain for a robotics expert than a rapeseed field in Emsland,” he admits with a laugh. “But when it comes to social relevance, agricultural technology beats space technology hands down.”

Moritz Münch for VolkswagenStiftung

In the workshop at Gut Arenshorst near Osnabrück, Benjamin Kisliuk and his colleague Gurunatraj Parthasarathy (right) get the robot ready to drive.

Learning to navigate

On Mars, and it’s no different in Emsland, navigation is one of the biggest challenges for an autonomous robot. There are many possible applications for the devices. Whether they only collect data, like the machine from Kisliuk’s team, or actively intervene in the growing of the crop, doing things such as weeding, sowing or harvesting: The robot must always know exactly where it is and where it is allowed to go. “There’s a rule in robotics or when teaching machines in general: The things that people find easy is often what machines have the biggest problems with,” says Kisliuk. “That was the case 30 years ago, and it hasn’t changed to this day.” An outdoor robot carefully programmed to avoid collisions would automatically stop when anything at all is in its way, such as a single, tall blade of grass – even if the area all around is completely clear. “For a human, of course, that’s no problem at all. But teaching a machine whether an object in the path ahead can or cannot be driven over is no easy matter,” explains the researcher.

What’s more, unlike other outdoor robots, which have long been able to use radar, laser, and sonar technology to navigate through the terrain, agricultural robots are not intended to follow predefined paths such as forest tracks, but must be able to move through a field full of plants, each one of which basically presents an obstacle for a laser scanner. “One solution might be to let the machine drive to the edge of the field guided by its sensors with collision detection, and as soon as it gets there to have the system switch the sensors off.” But that would of course be highly problematic, Kisliuk points out. “Our robot already weighs more than 200 kilograms. Imagine an autonomous device weighing several tons. It would of course be totally irresponsible to let such a machine drive across a field without a safety system: there could be animals in the way or, in the worst case, even people.”

Moritz Münch for VolkswagenStiftung

Using various cameras, including stereo laser and thermal cameras, the agricultural robot generates detailed data on the condition of the plants.

Laser gun against weeds

Instead of obstacle recognition, Kisliuk therefore relies on GPS data, which is already available in high resolution for agricultural purposes, to navigate his robot. “This allows us to define the paths that the robot is allowed to follow with great precision.” In addition, so-called semantic maps can be created on the basis of drone and satellite data, which define certain properties for specific areas. For example, a robot can recognize whether a lawn is a garden or a pasture. There are also external inputs that the machine can use for navigation – such as information on soil conditions. “We can teach the robot not to drive over a field after rainfall in order to avoid the risk of it getting stuck in the mud.”

As for the future, Kisliuk hopes to be able to use the infrastructure established at the DFKI location in Osnabrück for further research projects in the field of smart farming – with the support of the Lower Saxony Ministry of Science and the Volkswagen Foundation. Once the robot has learned to navigate, it will be possible to focus on applications that go beyond simply collecting data. In a recently launched project at DFKI in Lower Saxony, laser technology is to be used for weed control. For fire safety reasons, the plants are not killed by burning, but by being subjected to high temperatures of around 60 degrees.

Star Wars in the fields? “The project may sound a little strange at first,” admits Kisliuk. “But the exciting thing is that you can carry out a much larger number of hands-on experiments working in the fields than when developing a Mars rover.”

Moritz Münch for VolkswagenStiftung

Test tacker at Gut Arenshorst, where the DFKI robots are tested in the field.